Nickel Alloy 20 (UNS N08020) /DIN2.4660

|

Alloy |

element |

C |

Si |

Mn |

S |

P |

Ni |

Cr |

Nb+Ti |

Fe |

Cu |

Mo |

|

Alloy 20 |

Min |

|

|

|

|

|

32.0 |

19.0 |

8*C |

|

3.0 |

2.0 |

|

Max |

0.07 |

1.0 |

2.0 |

0.035 |

0.045 |

38.0 |

21.0 |

1.0 |

balance |

4.0 |

3.0 |

|

Aolly Status |

Tensile strength Rm Mpa Min. |

Yield strength RP 0. 2 Mpa Min |

Elongation A 5 min % |

|

Annealed |

620 |

300 |

40 |

|

Density g/cm3 |

|

8.08 |

Rod, Bar, Wire and Forging Stock - ASTM B 462 ASTM B 472, ASTM B 473, ASME SB 472, ASME SB 473,

Plate, Sheet and Strip - ASTM A 240, ASTM A 480, ASTM B 463, ASTM B 906, ASME SA 240,

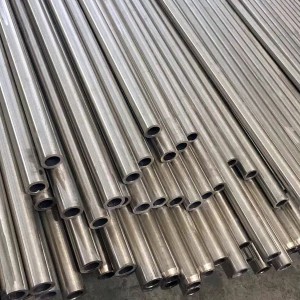

Pipe and Tube - ASTM B 729, ASTM B 829, ASTM B 468, ASTM B 751, ASTM B 464, ASTM B 775, ASTM B 474,

Other - ASTM B 366, ASTM B 462, ASTM B 471, ASTM B 475, ASME SB 366, ASME SB-462, ASME SB

Excellent general corrosion resistance to sulfuric acid

Excellent resistance to chloride stress corrosion cracking

Excellent mechanical properties and fabricability

Minimal carbide precipitation during welding

Excels in resisting corrosion to hot sulfuric acids